![]() > Technology

> LS-CVD

> Technology

> LS-CVD

Semiconductor technologies have been developing in accordance with Moore's Law. However, once the line width decreased to 22 nm, it becomes difficult to downsize the line width further. Now, a new technology called TSV (Through Silicon Via) gets attention. TSV is the technology used to connect circuit chips in 3 dimensions. TSV requires low-temperature deposition of high-coverage insulating film. SiH4 is generally used to deposit SiO2 film, but is not safe as because it is toxic and explosive. samco-ucp has been working on an alternative to SiH4, Liquid Source TEOS, for more than 20 years.

The LS-CVD system is the plasma CVD system that uses Liquid Source as a precursor. TEOS is easier and safer SiH4 to handle yet can create as good a film as SiH4. LS-CVD system can deposit not only SiO2 film but also DLC films by using hydrocarbon liquid monomer as a precursor.

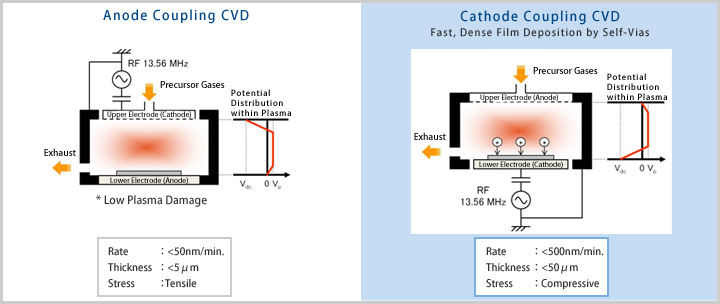

LS-CVD with cathode coupling method is samco-ucp's unique technology. Cathode coupling vaporizes liquid source and utilizes ions effectively. The high electric field on the cathode enables good control on film stress and density by its fine control of ion energy, and achieves great coverage. Additionally, cathode coupling enables low-temperature deposition as self bias collects ions, facilitating film deposition.

Synergy of TEOS and cathode coupling enables high quality and coverage of TEOS-SiO2 film on high aspect ratio via hole in TSV process.

samco-ucp's LS-CVD systems are used widely from insulation film deposition in TSV, mask creation on MEMS, and formation of oxidized sacrifice layer, to creation of optical waveguides, by many users.