Corresponding systems: RIE-200iPC

Gallium nitride (GaN) is now illuminating the future of optoelectronics and

power devices. samco-ucp continues to provide high quality GaN etching solutions,

most notably the RIE-200iPC (a cassette-to-cassette etching system specifically designed for stable, precise, and highly selective anisotropic GaN etching).

GaN Etching Capability:

- Low damage, repeatable recess etching (1 nm/min) with smooth bottoms for AlGaN thickness control

- Anisotropic or reverse-taper etching with smooth sidewalls

- Gate formation using highly selective GaN/AlGaN etching

- GaN/AlGaN selectivity of over 100:1

- SiN/AlGaN selectivity of over 100:1

- Stable, low etch rate of 0.8 nm/min at bias RF power of 5W

- Uniformity of more than ±1.11% across a 6" wafer

- Electrostatic chuck, helium backside cooling, and heat-resistant photoresist processing combine to keep wafer temperature low and prevent photoresist deformation

- Pre-treatment for reduced offset time and process stabilization increases etch depth accuracy

- Optimized process chamber with plasma discharge monitor

- Load-lock chamber with multi-joint arm type robot for direct wafer transfer under vacuum

- Cassette chamber with vacuum elevator robot for higher throughput

- Endpoint detection system for greater etch depth control

|

Reverse-taper GaN Etch

AlGaN Recess Etch (RIE-200iP) |

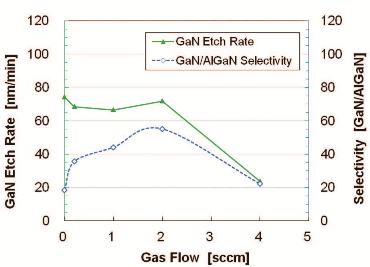

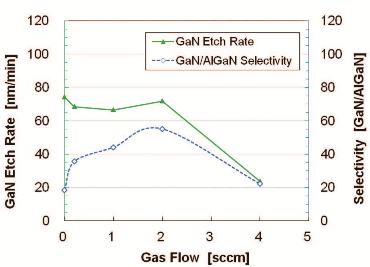

Gas Flow Effect on GaN Etch Rate and GaN/AlGaN Selectivity

|

Bias Power Effect on AlGaN Etch Rate

|

Related Articles:

Chlorine-Based ICP Etching for Improving the Luminance Efficiency in Nitride LEDs

Breakthrough for Next Generation Power Devices

![]() > Technology

> Processes

> GaN/AlGaN Etch for LED

> Technology

> Processes

> GaN/AlGaN Etch for LED